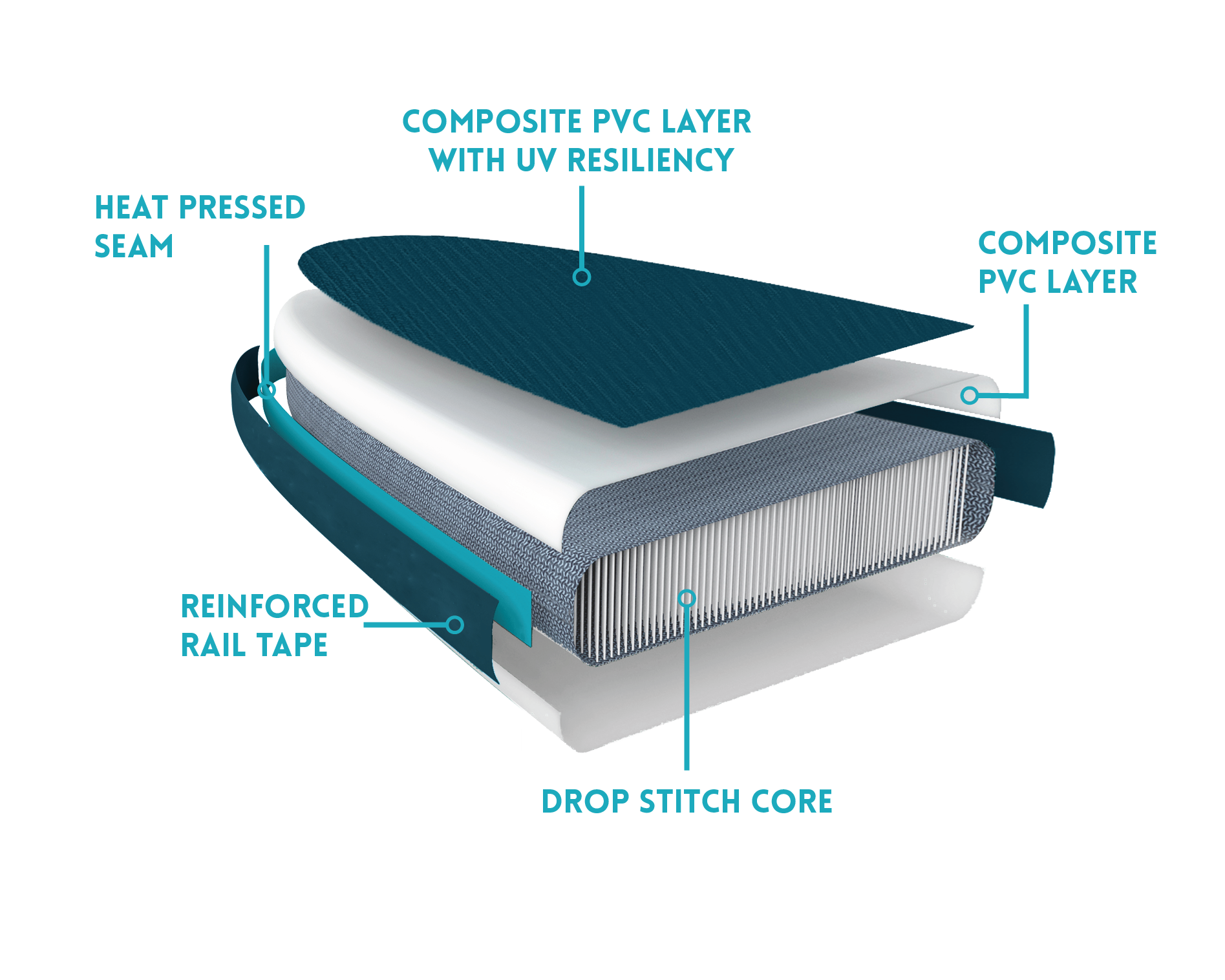

The OUTO paddle board is crafted using the innovative AirLEV technology. This technology incorporates multiple drop stitches that interconnect the upper and lower layers of the board, resulting in a durable and stable surface when inflated.

The board's exterior layer is fortified with military-grade PVC and rail tapes that are heat-sealed to provide extra protection. The board is designed to withstand various impacts and conditions, ensuring that riders can enjoy their paddleboarding experience safely.

Overall, the OUTO Paddle Board is built with a sturdy construction that guarantees reliability and longevity.

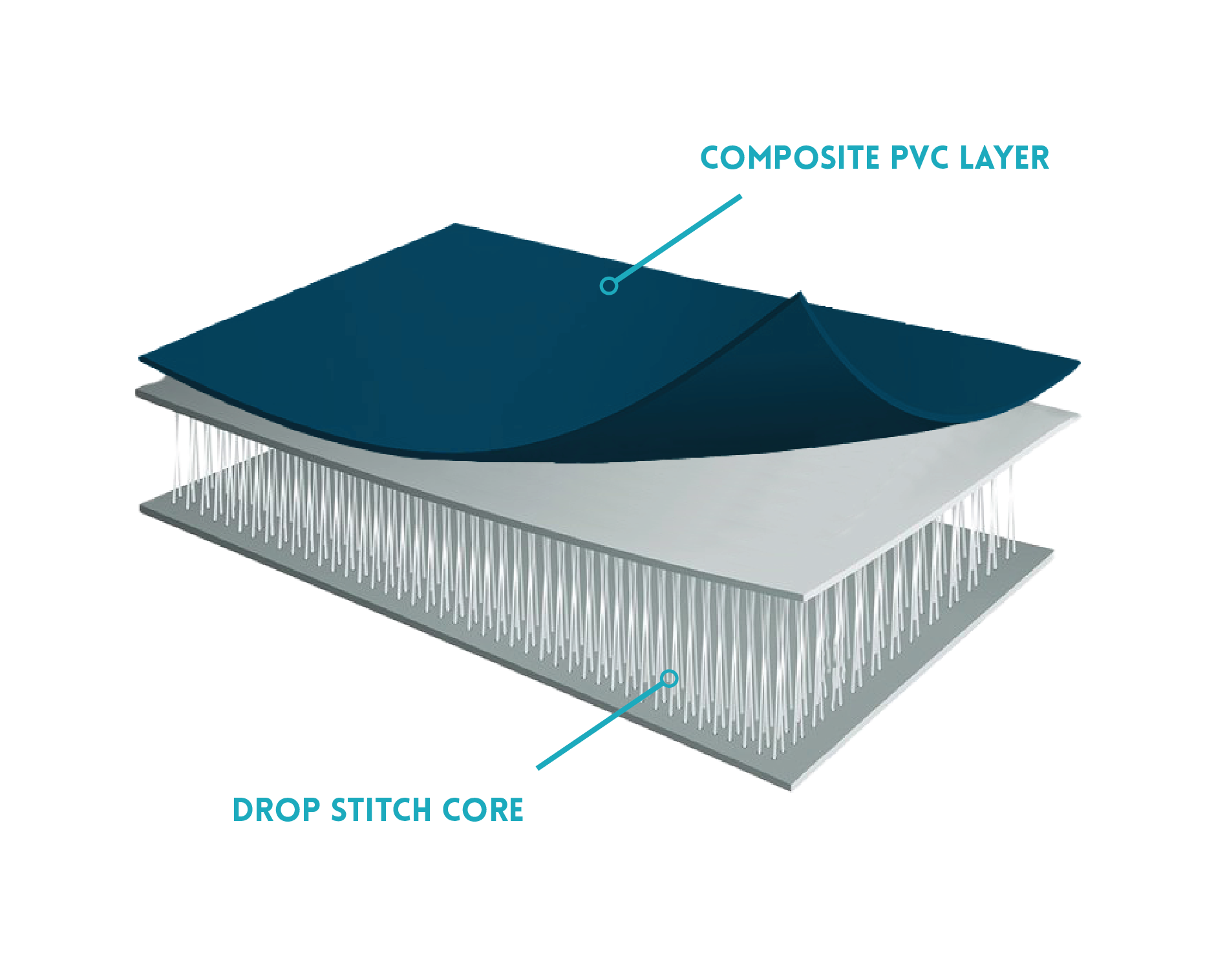

Drop stitch technology is a method for constructing inflatable objects, such as paddle boards, that allows for high-pressure inflation and a rigid structure.

In drop stitch construction, thousands of small threads connect the top and bottom panels of the board, creating a strong and stable surface. When inflated, the board becomes rigid and able to support weight, while remaining lightweight and easy to transport.

This technology has revolutionized the inflatable paddle board industry by making it possible to create durable, reliable, and user-friendly boards.

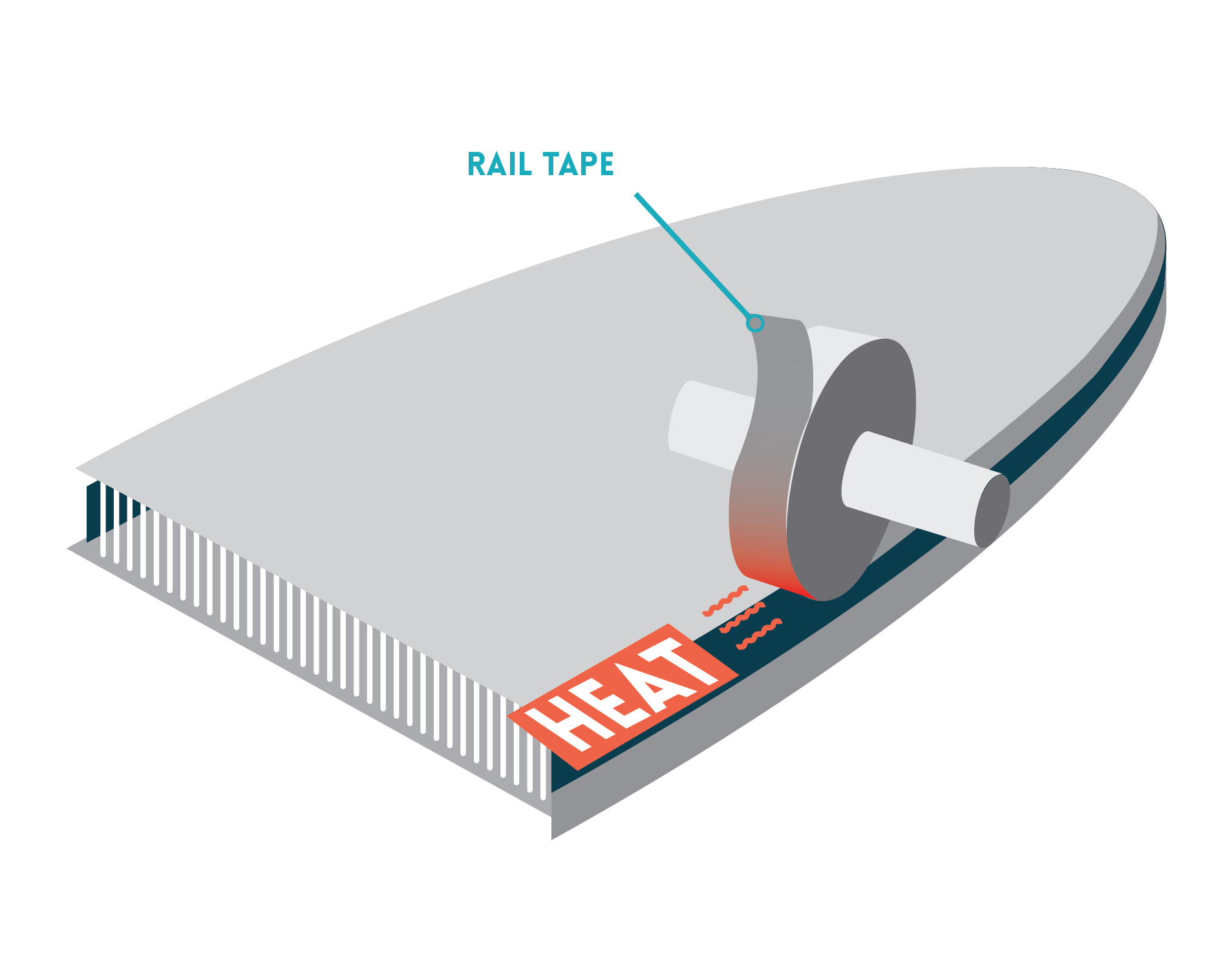

Heat pressed rail tape is a type of tape used to reinforce the rails or edges of an inflatable paddle board. Using heat and pressure, this tape creates a strong and permanent bond with the board, which enhances its durability and longevity.

This tape is important because it helps protect the board from damage caused by rocks, sand, and other hazards that can be encountered on the water. It also extends the life of the board by reinforcing the areas most susceptible to wear and tear.